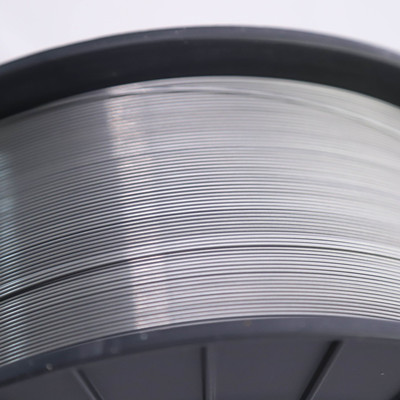

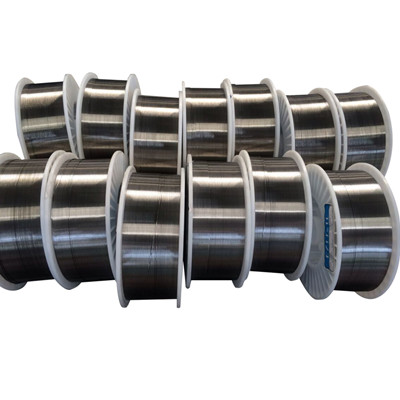

50 kg grade structure steel gas shield flux cored wire

AWS E71T-1C

APPLICATIONS:

E71T-1C is a kind of Titania type CO2 gas shielded flux-cored welding wire for low-carbon steel and 490MPa high strength steel.

CHARACTERISTICS:

This wire is CO2 gas shielded flux cored wire of titanium slag system,applying for all position welding,

with excellent mechanical properties and process performance.

When welding is small, the arc is stable and soft.effortless slag removal, the weld molding is beautiful.

ATTENTION:

1.Direct Current Electrode Positive(DCEP)welding.(Welding wire connecting anode)

2, Use CO2 as shielded gas ,whose purity is more than 99.9%, and flow rate is 20-25L/min.

3, when in multi pass welding, keep the layer temperature at about 150 to 200 degrees celsius.

4, In order to prevent the occurrence of pores, please the remove the grease and rust from the surface of base metal before welding

5, the preservation of welding wire: wire has been taken measures to resist moisture before using.

It should be used as soon as possible when opening the package , do not leave the welding wire has not been used up for a long time in the air.

6,Due to the softer solid wire ,do not lock the pressure roller of wire feeding device too tight.

WELDING POSITION: PA,PB,PC,PD,PE,PF

TYPE OF CURRENT/GAS: DC+/CO2

Typical Chemical Composition Of Deposited Metal(wt%):

|

C

|

Mn

|

Si

|

P

|

S

|

Others

|

|

0.05

|

1.35

|

0.45

|

0.012

|

0.01

|

-

|

Typical Mechanical Properties Of Deposited Metal:

|

Y.P.(MPa)

|

T.S.(MPa)

|

E.L.(%)

|

I.V.(J)

|

|

480

|

580

|

27

|

-20°C/128

|

electrode,electrodes,welding,welding electrode,welding electrodes,welding rod,welding rods,welding electrode price,electrode welding,welding rod factory price,welding stick,stick welding,welding sticks,china welding rods,stick electrode,welding consumables,welding consumable,China electrode,welding electrodes China,carbon steel welding electrode,carbon steel welding electrodes,welding electrode factory,Chinese factory welding electrode,China welding electrode,China welding rod,welding rod price,welding supplies,wholesale welding supplies,global welding supplies,arc welding supplies,welding material supply,arc welding,steel welding,easy arc welding electrode,arc welding electrode,arc welding electrodes,vertical welding electrode,price of welding electrodes,cheap welding electrode,acid welding electrodes,alkaline welding electrode,cellulosic welding electrode,china welding electrodes,factory electrode,small size welding electrodes,welding materials,welding material,welding rod material,welding electrode holder,nickel welding rod,j38.12 e6013,welding rods e7018-1,welding stick electrode,welding rod 6010,welding electrode e6010,welding rod e7018,welding electrode e6011 ,welding rods e7018,welding electrodes 7018,welding electrodes e7018,welding rod 6013,welding rods 6013,welding electrode 6013,welding electrode e6013,6010 welding rod,6010 welding electrode,6011 welding rods,6011 welding electrodes,6013 welding rod,6013 welding rods,6013 welding electrode,6013 welding electrodes,7024 welding rod,7016 welding rod,7018 welding rod,7018 welding rods,7018 welding electrode,7018 welding electrodes,welding electrode e7016 ,e6010 welding rod,e6011 welding rod,e6013 welding rod,e7018 welding rod,e6013 welding electrode,e6013 welding electrodes,e7018 welding electrode,e7018 welding electrodes,J421 welding electrode,J422 welding electrodes,welding electrode J422,wholesale e6010,wholesale e6011,wholesale e6013,wholesale e7018,best welding electrode,best welding electrode J421,stainless steel welding electrode,stainless steel welding rod,stainless steel electrode,SS welding electrode,welding rods e307,welding electrode e312,309l welding rod,316 welding electrode,e316l 16 welding electrodes,cast iron welding electrode,aws Eni-Ci,aws Enife-Ci,surfacing welding,hard facing welding rod,hard surfacing welding,hardfacing welding, welding, welding,vautid welding,bohler welding,lco welding,miller welding,atlantic welding, welding,flux powder,welding flux,welding powder,welding electrode flux material ,welding electrode flux,welding electrode material,tungsten electrode,tungsten electrodes,welding wire,argon arc welding,mig welding,tig welding,gas arc welding,gas metal arc welding,electric are welding,electric arc welding,arc welding rods,carbon arc welding,e6013 welding rod uses,types of welding electrodes,flux core welding,types of electrodes in welding,welding supply,welding metal,metal welding,shielded metal arc welding,aluminum welding,welding aluminum with mig,aluminum mig welding,pipe welding,welding types,types of welding rod,all types of welding,welding rod types,6013 welding rod amperage,welding rods electrodes,welding electrode specification ,welding electrode classification ,welding electrode aluminium ,welding electrode diameter ,mild steel welding,stainless steel welding,e6011 welding rod uses,welding rods sizes,welding rods price,welding electrodes size,aws e6013,aws e7018,aws er70s-6,stainless steel welding wire,stainless steel mig welding wire,tig welding wire,low temp welding rod,6011 welding rod amperage,4043 welding rod,cast iron welding rod,western welding academy,sanrico welding rods,aluminium welding,aluminium welding rod,welding products,welding tech,welding factory

Previous: MIG TIG cooper coated solid welding wire ER80s-G

Next: E71T-11 Mild Steel Flux Cored Welding Wires