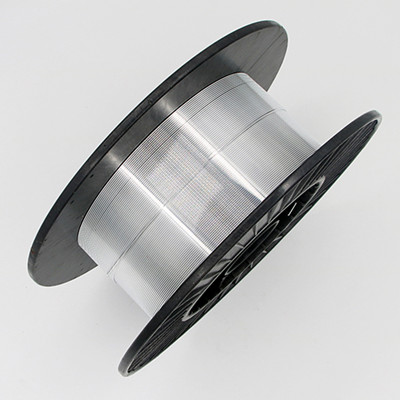

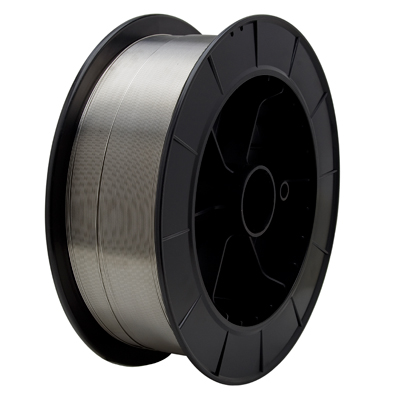

ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047

APPLICATION:

Used for jointing or overlay light alloy processing. It also widely used as filler materials in argon arc welding and oxyacetylene gas welding.

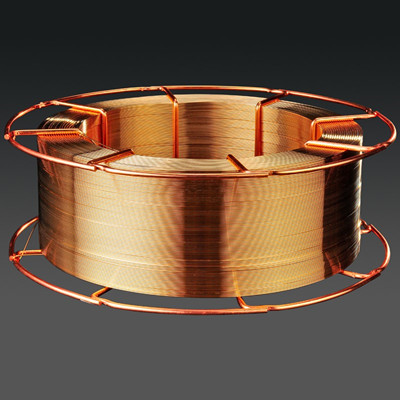

Argon arc welding is a perfect method for welding copper aluminum alloy.

Argon arc welding can not use flux, but oxyacetylene gas welding needs to use aluminum gas welding flux.

The selection of welding wire is mainly based on the type of base metal and the requirements of crack resistance, mechanical properties and corrosion resistance of the joint.

INTRODUCTION:

ER4047 is the eutectic aluminum silicon alloy welding wire with about12% Si element.

Suitable for Al-Si, Al-Si-Mg, Al Si mg Cu wrought aluminium and aluminium (7%Si) argon arc welding. Low melting point and good fluidity.

CHARACTERISTICS:

- Welding Filler Wire

- Spray and Flame Metallizing Wire

- Similar to AlSi12 (Germany), BS N21 (United Kingdom)

- Lower melting point and higher fluidity than 4043 wires

- Can be used as a substitute for 4043 wires to increase silicon in the weld metal, minimize hot cracking and produce higher fillet weld shear strength

- widely used for brazing of aluminum, Al-Mn, Al-Si-Mg alloy materials

SPECIFICATION:

MIG: 0.6mm; 0.8mm; 0.9mm; 1.0mm; 1.2mm; 1.6mm

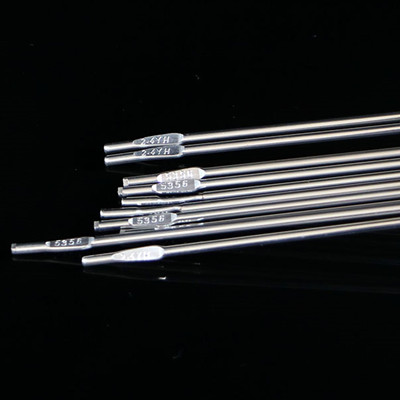

TIG: 1.2mm; 1.6mm; 2.0mm; 2.4mm; 3.0mm; 4.0mm;

Typical Chemical Composition Of Deposited Metal:

| Cu |

Si |

Fe |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 0.3 |

11.0-13.0 |

0.80 |

0.15 |

0.10 |

0.05 |

0.20 |

- |

Rem |

electrode,electrodes,welding,welding electrode,welding electrodes,welding rod,welding rods,welding electrode price,electrode welding,welding rod factory price,welding stick,stick welding,welding sticks,china welding rods,stick electrode,welding consumables,welding consumable,China electrode,welding electrodes China,carbon steel welding electrode,carbon steel welding electrodes,welding electrode factory,Chinese factory welding electrode,China welding electrode,China welding rod,welding rod price,welding supplies,wholesale welding supplies,global welding supplies,arc welding supplies,welding material supply,arc welding,steel welding,easy arc welding electrode,arc welding electrode,arc welding electrodes,vertical welding electrode,price of welding electrodes,cheap welding electrode,acid welding electrodes,alkaline welding electrode,cellulosic welding electrode,china welding electrodes,factory electrode,small size welding electrodes,welding materials,welding material,welding rod material,welding electrode holder,nickel welding rod,j38.12 e6013,welding rods e7018-1,welding stick electrode,welding rod 6010,welding electrode e6010,welding rod e7018,welding electrode e6011 ,welding rods e7018,welding electrodes 7018,welding electrodes e7018,welding rod 6013,welding rods 6013,welding electrode 6013,welding electrode e6013,6010 welding rod,6010 welding electrode,6011 welding rods,6011 welding electrodes,6013 welding rod,6013 welding rods,6013 welding electrode,6013 welding electrodes,7024 welding rod,7016 welding rod,7018 welding rod,7018 welding rods,7018 welding electrode,7018 welding electrodes,welding electrode e7016 ,e6010 welding rod,e6011 welding rod,e6013 welding rod,e7018 welding rod,e6013 welding electrode,e6013 welding electrodes,e7018 welding electrode,e7018 welding electrodes,J421 welding electrode,J422 welding electrodes,welding electrode J422,wholesale e6010,wholesale e6011,wholesale e6013,wholesale e7018,best welding electrode,best welding electrode J421,stainless steel welding electrode,stainless steel welding rod,stainless steel electrode,SS welding electrode,welding rods e307,welding electrode e312,309l welding rod,316 welding electrode,e316l 16 welding electrodes,cast iron welding electrode,aws Eni-Ci,aws Enife-Ci,surfacing welding,hard facing welding rod,hard surfacing welding,hardfacing welding, welding, welding,vautid welding,bohler welding,lco welding,miller welding,atlantic welding, welding,flux powder,welding flux,welding powder,welding electrode flux material ,welding electrode flux,welding electrode material,tungsten electrode,tungsten electrodes,welding wire,argon arc welding,mig welding,tig welding,gas arc welding,gas metal arc welding,electric are welding,electric arc welding,arc welding rods,carbon arc welding,e6013 welding rod uses,types of welding electrodes,flux core welding,types of electrodes in welding,welding supply,welding metal,metal welding,shielded metal arc welding,aluminum welding,welding aluminum with mig,aluminum mig welding,pipe welding,welding types,types of welding rod,all types of welding,welding rod types,6013 welding rod amperage,welding rods electrodes,welding electrode specification ,welding electrode classification ,welding electrode aluminium ,welding electrode diameter ,mild steel welding,stainless steel welding,e6011 welding rod uses,welding rods sizes,welding rods price,welding electrodes size,aws e6013,aws e7018,aws er70s-6,stainless steel welding wire,stainless steel mig welding wire,tig welding wire,low temp welding rod,6011 welding rod amperage,4043 welding rod,cast iron welding rod,western welding academy,sanrico welding rods,aluminium welding,aluminium welding rod,welding products,welding tech,welding factory

Previous: Hot-selling China Aws-A5.23/A5.17 Welding Flux Sj301 for Submerged Arc Welding

Next: MIG TIG solid welding wire AWS ER4303 ER5356 for aluminum welding 7kg per plastic spool