Popular Design for 3.2 Mm Welding Rods Amps - Brass Gas Welding Rods Brass brazing rod HS221 Brazing alloy HS221 CuZn40 – Tianqiao

Popular Design for 3.2 Mm Welding Rods Amps - Brass Gas Welding Rods Brass brazing rod HS221 Brazing alloy HS221 CuZn40 – Tianqiao Detail:

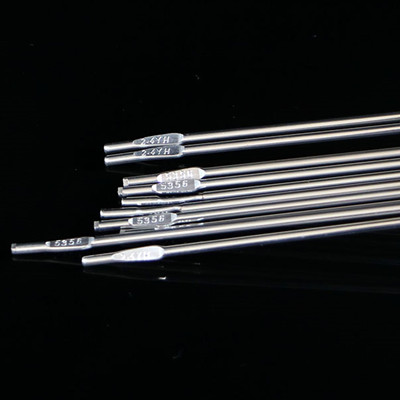

Brass Gas Welding Rods Brass brazing rod HS221 Brazing alloy HS221 CuZn40

Low fuming bronze RBCuZn-A Brass Gas Welding Rods

Chemical Composition ( % ):

| Standard | Class | Alloy | Cu | Al | Fe | Mn | Ni | P | Pb | Si | Sn | Zn | Other |

| ISO24373 | Cu4700 | CuZn40Sn | 57.0-61.0 | 0.01 | - | - | - | - | 0.05 | - | 0.25-1.0 | bal | 0.5 |

| GB/T9460 | SCu4700 | CuZn40Sn | 57.0-61.0 | Max 0.01 | - | - | - | - | Max 0.05 | - | 0.25-1.0 | bal | Max 0.5 |

| BS EN14640 | Cu4700 | CuZn40 | 57.0-61.0 | 0.01 | - | - | - | - | 0.05 | - | 0.25-1.0 | bal | 0.5 |

| AWS A5.8 | C47000 | RBCuZn-A | 57.0-61.0 | 0.01 | - | - | - | - | 0.05 | - | 0.25-1.0 | bal | 0.5 |

Physical Properties and Mechanical Properties:

|

Solids-Temperature |

886°C |

Liquids-Temperature |

901°C |

|

|

Density |

8.45kg/dm3 |

Tensile Strength |

375N/mm2 |

|

|

Elongation |

35% |

Brinell Hardness |

85HB |

Applications

Most popular for padding material of gas-welding and carbon are welding in brass. Can also used in brazing of copper, steel, copper-nickel, cast iron and carbide cutting alloy tools incrustation.

Chemical Composition ( % ):

| Standard | Class | Alloy | Cu | Al | Fe | Mn | Ni | P | Pb | Si | Sn | Zn | Other |

| ISO24373 | Cu4641 | CuZn40SnSi | 58.0-62.0 | 0.01 | 0.2 | 0.3 | - | - | 0.03 | 0.1-0.5 | 1.0 | bal | 0.2 |

| GB/T9460 | SCu6810A | CuZn40SnSi | 58.0-62.0 | Max 0.1 | Max 0.2 | Max 0.3 | - | - | Max 0.03 | 0.1-0.5 | Max 1.0 | bal | Max 0.2 |

| BS EN14640 | SCu6810 | CuZn40SnSi | 58.0-62.0 | 0.01 | 0.2 | 0.3 | - | - | 0.03 | 0.1-0.5 | 1.0 | bal | 0.2 |

| DIN 1733 | 2.0366 | SG-CuZn40Si | 58.0-62.0 | Max 0.01 | Max 0.2 | Max 0.3 | - | - | Max 0.03 | 0.1-0.5 | Max 1.0 | bal | Max 0.2 |

Physical Properties and Mechanical Properties:

|

Solids-Temperature |

870-890°C |

Liquids-Temperature |

880-910°C |

|

|

Density |

8.4kg/dm3 |

Tensile Strength |

381N/mm2 |

|

|

Elongation |

30% |

Brinell Hardness |

88HB |

Advantages:

1.Good wear resistance of Brass Gas Welding Rods.

2.Excellent corrosion resistance;

3.High intensity.

4.Suface clean, Good smooth

Package details:

- 5kg or 10kg/shrink film; 500kgs/wooden case

- As per your requirement

Business term: CIF, CNF, FOB

OEM is acceptable; and free samples.

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

Popular Design for 3.2 Mm Welding Rods Amps - Brass Gas Welding Rods Brass brazing rod HS221 Brazing alloy HS221 CuZn40 – Tianqiao, The product will supply to all over the world, such as: , , ,