Manufacturer for Welding Materials - Rutile sand for welding electrode production – Tianqiao

Manufacturer for Welding Materials - Rutile sand for welding electrode production – Tianqiao Detail:

Product Description:

Rutile is the main mineral composition of titanium dioxide (TiO2), and is the most common natural form of TiO2. It exists in powder form in nature and is dark brown to black dry free running sand. Rutile gets its name from the Latin “rutilus”. In beach sands, rutile is abundant enough to be an important component of heavy minerals and deposits. Miners extract and separate valuable minerals such as rutile, zircon and ilmenite.

Main uses and role in welding materials:

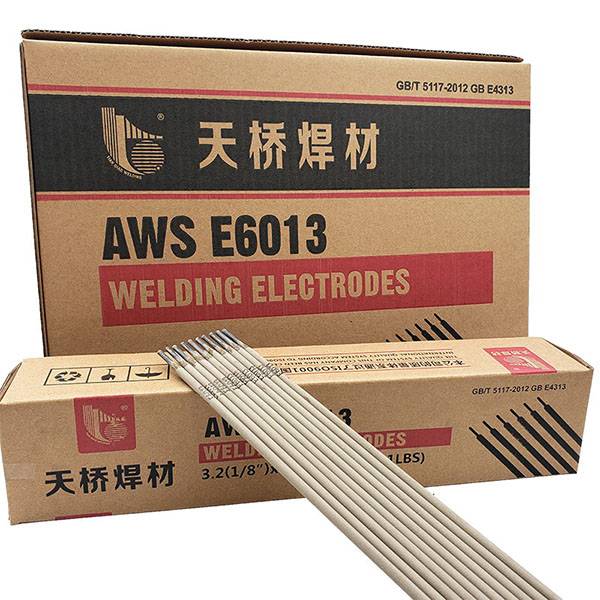

Rutile is the main raw material of welding rod and sintered flux, and it is also the main raw material of high-titanium potassium type and titanium calcium type welding rod. The main components of the coating of E6013 and J422 electrodes are natural rutile and ilmenite. Rutile is a slag-forming agent, which can adjust the melting point of welding slag, improve weld formation, refine droplets and improve welding process performance.

COMMON INFORMATION:

|

Products names: |

Rutile Sand |

|

CAS number: |

1317-80-2 |

|

Formula: |

TiO2 |

|

Harmonize Commodity Code: |

2614009000 |

СНEMICAL COMPOSITION (%):

|

TiO2 |

≥94% |

|

SiO2 |

≤1.5% |

|

Fe2O3 |

≤1.0% |

|

ZrO2 |

≤1.0% |

|

Al2O3 |

≤0.6% |

|

P2O5 |

<0.05% |

|

SO3 |

<0.05% |

|

Moisture |

<0.5% |

PHYSICAL DESCRIPTION AND PROPERTIES:

|

Appearance: |

Dark brown to black dry free running sand. |

|

Grain shape: |

Elongated, rolled. |

|

Grain color: |

Red (different tints), brown, black. |

|

Melting point: |

1850 °С |

|

Flammable: |

Nonflammable |

|

Solubility in Water: |

Insoluble |

|

Grain size: |

60-200Mesh |

Applications: Making welding electrode/flux cored welding wire/sintered flux.

Store: Keep in ventilated and dry places, prevent from goods that may affect the quality of the goods, against damp.

Shipment: 1ton net in anti-damp bag (big bag).

Notes: Carefully load and unload, be care not pollute or torn the package, avoid rain and insolation during transportation.

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for Manufacturer for Welding Materials - Rutile sand for welding electrode production – Tianqiao, The product will supply to all over the world, such as: Marseille, Malaysia, Bhutan, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that customer first and committed to helping customers expand their business, so that they become the Big Boss !

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.