Factory Free sample Vacuum Pack Electrodes - Stainless Steel Welding Electrode AWS E308-16 (A102) – Tianqiao

Factory Free sample Vacuum Pack Electrodes - Stainless Steel Welding Electrode AWS E308-16 (A102) – Tianqiao Detail:

APPLICATIONS:

It can be used to the corrosion resistance of stainless steel structure, such as the 06Cr19Ni9 and 06Cr19Ni11Ti, whose working temperature below 300 ℃; it can also be used for stainless steel structure using under cryogenic temperatures, such as liquid nitrogen container, liquefied natural gas containers, etc.

CHARACTERISTICS:

E308-16 is a coated rutile type Cr18Ni9 stainless steel. Both AC and DC can be used and can be all-position welding. It can reach excellent welding performance, stable arc, little spatter, easy slag removal and good weld appearance. The deposited metal has good resistance to inter granular corrosion.

ATTENTION:

1. The electrodes must be baked by 320-350 ℃ for 1 hour before welding, dry the electrode when use it.

2. The rust, oil, water and other impurities of the weld must be removed before welding.

3.Recommended DC power supply, because AC welding has a shallow penetration, the current should not be too large, in order to avoid the coating redness and cracking.

4. To minimize the amount of heat input and welding electrode oscillating amplitude should not be too big.

5. Preheat and interlayer-temperature should remain below 150 ℃

WELDING POSITIONS:

PA, PB, PD, PF

DEPOSIT COMPOSITION (Quality Score): %

|

items |

C |

Cr |

Ni |

Mo |

Mn |

Si |

P |

S |

Cu |

|

Requirements |

≤0.08 |

18.0-21.0 |

9.0-11.0 |

≤0.75 |

0.5-2.5 |

≤1.00 |

≤0.04 |

≤0.03 |

≤0.75 |

|

Typical Results |

0.062 |

19.34 |

10.14 |

0.28 |

1.08 |

0.66 |

0.025 |

0.010 |

0.08 |

MECHANICAL PROPERTIES:

|

items |

Tensile Strength Rm/MPa |

Elongation A/% |

Charpy V-Notch KV2(J)-196℃ |

|

Requirements |

≥550 |

≥30 |

≥29 |

|

Typical Results |

570 |

38 |

36 |

TYPICAL OPERATING PROCEDURES: (AC, DC+)

| Diameter (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

| Current (A) |

25-50 |

50-80 |

80-110 |

110-160 |

160-200 |

PACKAGING:

5kg/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21MT -26MT per 1X20″ FCL.

OEM/ODM:

We support OEM/ODM and could make packaging accord to your design, please contact us for detail discussion.

General requirements:

The manufacture of welded structural parts shall comply with the design, process documents and the provisions of this standard. 3.2 Requirements for ambient temperature during welding production:

When parts and finished products are rectified, the temperature should not be lower than the following:

Low carbon steel material: -20℃;

Low alloy structural steel material: -15℃.

Generally, the allowable welding temperature of welding parts should meet the requirements of Table.

When welding parts are welded under low temperature conditions (as listed in Table 1), the surface of the steel should be preheated. The width of the preheating zone must be greater than 4 times the thickness of the plate to be welded, and the preheating width on each side must not be less than 100mm. Welding can only be done after heating to 100~~200℃. If flame preheating is used, the distance between the flame core and the board surface should be greater than 50mm.

Under normal temperature conditions, for welding parts with high rigidity and poor weldability, preheating should also be carried out before welding (the preheating temperature is within the range of 100~200℃), and heat preservation or tempering should be carried out after welding to eliminate welding stress.

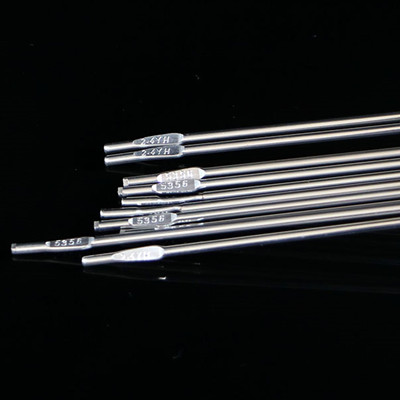

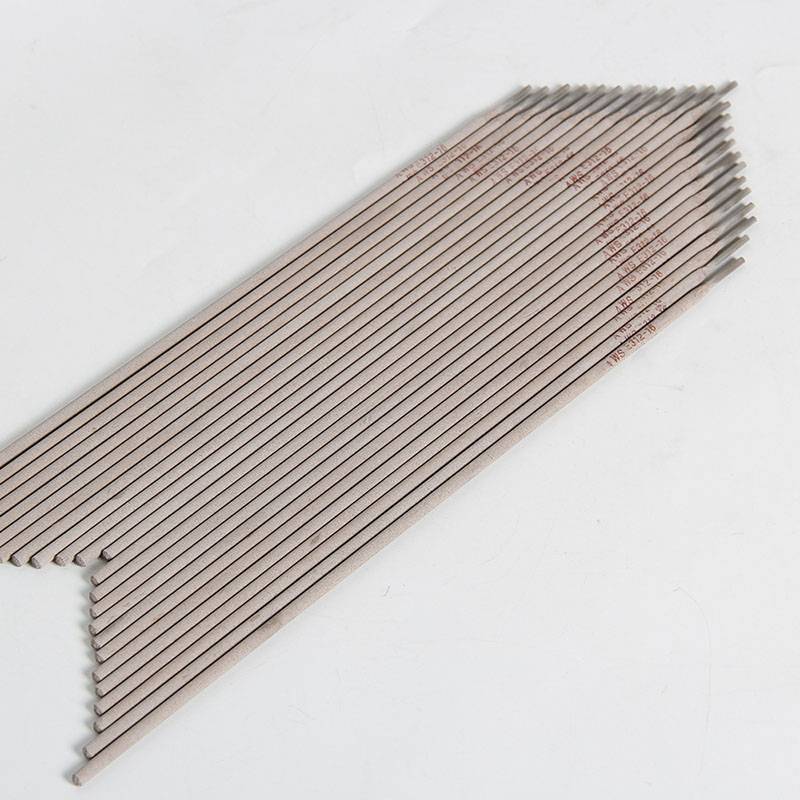

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

Factory Free sample Vacuum Pack Electrodes - Stainless Steel Welding Electrode AWS E308-16 (A102) – Tianqiao, The product will supply to all over the world, such as: , , ,