18 Years Factory 7014 Rod - Surfacing Welding Rod D608 – Tianqiao

18 Years Factory 7014 Rod - Surfacing Welding Rod D608 – Tianqiao Detail:

Introduction:

D608 is a kind of CrMo cast iron surfacing electrode with graphite type coating. AC/DC. DCRP (Direct CurrentReversed Polarity) is more suitable. Because the surfacing metal is Cr and Mo carbide with cast iron structure, the surfacing layer has higher hardness, higher wear-resistance and excellent silt and ore wear-resistance.

Applications:

Used for welding parts of agricultural machinery, mining equipment, etc. which receive grit wear and slight impact.

| Chemical Composition of Deposited Metal (%) | |||

| Chemical Composition | C | Mo | Cr |

| Guarantee Value | 2.50~4.50 | 3.00~5.00 | 3.00~5.00 |

Hardness of Surfacing Layer: HRC≥55

| Reference Current (AC, DC+) | |||

| Electrode Diameter(mm) | φ3.2 | φ4.0 | φ5.0 |

| Welding Current (A) | 90~120 | 130~160 | 170~210 |

Instructions:

1.The electrodes must be baked under about 250℃ for an hour before welding.

2.In surfacing welding, the weld should be preheated to 400-500℃. If the surfacing thickness permits, a surfacing layer can be made with J507 at first. Then surfacing welding should be done when there is enough heat. The weld should be cooled down slowly after welding.

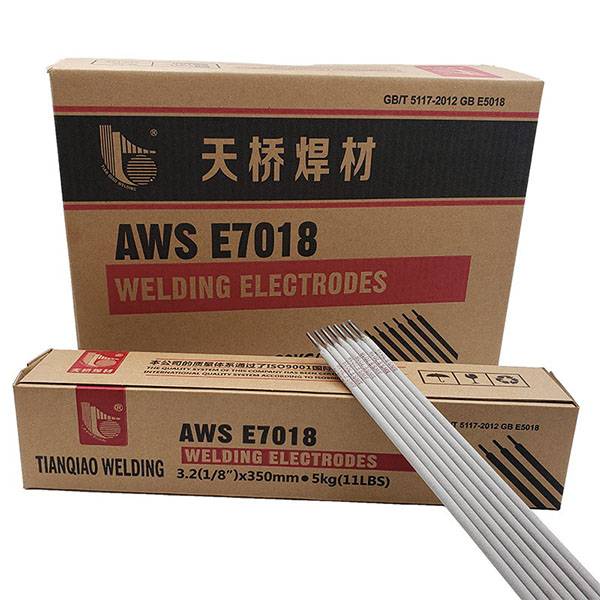

Packing details:

In carton of 20kgs/net, consisting of 8 boxes x 2.5kgs for 2.5mm, & 4 boxes x 5kgs for other sizes.

With/ without pallets (Fumigation-free pallets) upon customer’s request.

FAQ:

1.Hot specifications:

E6013, E6011, E6010, E7018, S.S. E308, E309, E310, E316

2.OEM design:

Yes, we can print your logo on the welding electrode; also make your brand packing box.

3.Free samples?

Yes, if you need 1 or 2 kgs. But the freight cost is paid by yourside.

4.Certifications:

ISO, SGS, our registered brand “ TIANQIAO” “YUANQIAO”, etc.

5.Delivery time?

10-15 days after we received your deposit.

6. MOQ?

One full 20ft container, that is 25tons.

7 . Payment term?

30% T/T in advance and balance before loading container.

8.Countries and regions exported ?

Europe: Germany, Poland, Italy, Netherlands…

North America: Canada, the USA;

South America: Peru, Chile, Brazil, Venezuela

South East Asia: Thailand, Cambodia, Vietnam, Philippines, Malaysia, Singapore, Indonesia.

9.Service time?

7*24, any time you need.

10.Team:

Factory with 20+ years experience in welding electrode formulation research and development

11.Quality Guarantee?

12 months quality warranty and exchange service against B/L date if any quality problem.

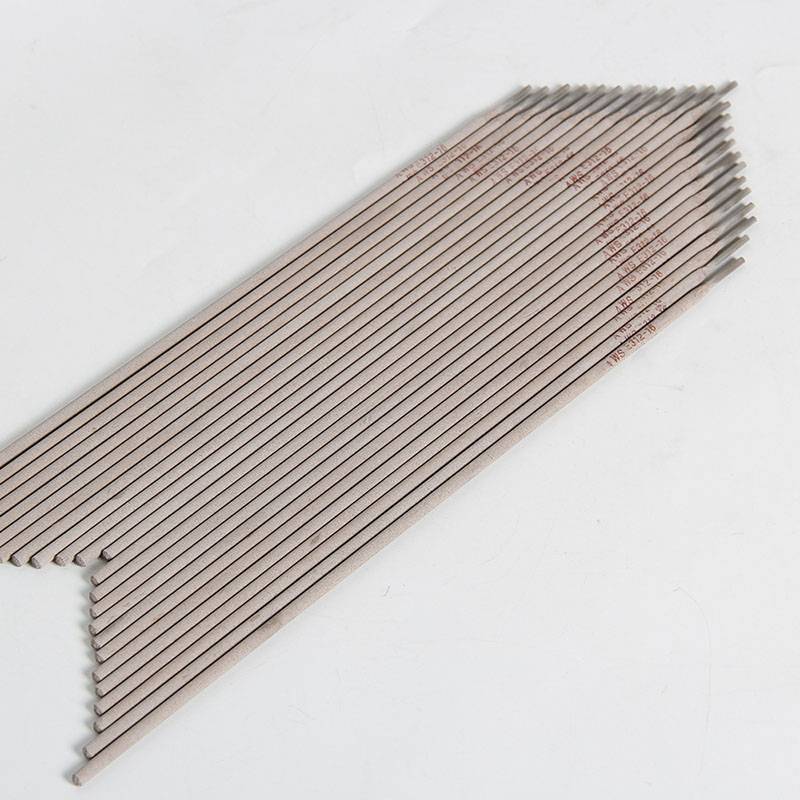

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for 18 Years Factory 7014 Rod - Surfacing Welding Rod D608 – Tianqiao, The product will supply to all over the world, such as: Czech, Israel, Chile, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!