The submerged arc welding process is the most ideal choice in the important application fields of pipelines, pressure vessels and tanks, track manufacturing and major construction. It has the simplest single wire form, double wire structure, series double wire structure and multi wire structure.

The submerged arc welding process can benefit users in many welding applications, from increased productivity to improved working conditions to consistent quality and more. Metal fabrication plants that are considering making changes to the submerged arc welding process should think of the many benefits that can be gained from this process.

Basic knowledge of submerged arc welding

The submerged arc welding process is suitable for heavy industrial application requirements of piping, pressure vessels and tanks, locomotive construction, heavy construction/excavation. Ideal for industries requiring high productivity, especially those involving welding of very thick materials, that can benefit greatly from the submerged arc welding process.

Its high deposition rate and travel speed can have a significant impact on worker productivity, efficiency and production costs, which is one of the key advantages of the submerged arc welding process.

Additional benefits include: welds with excellent chemical composition and mechanical properties, minimal arc visibility and low welding fume, improved work environment comfort, and good weld shape and toe line.

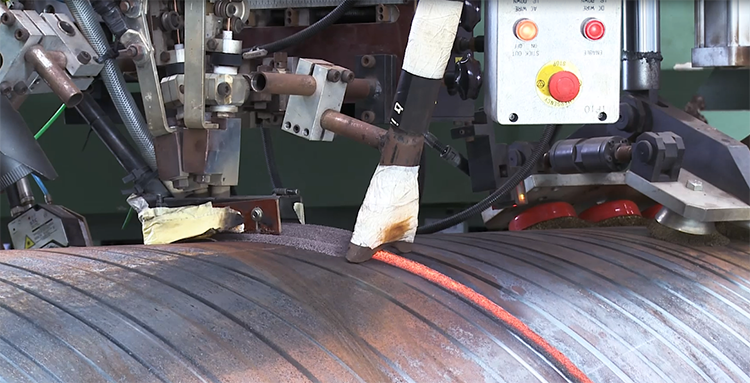

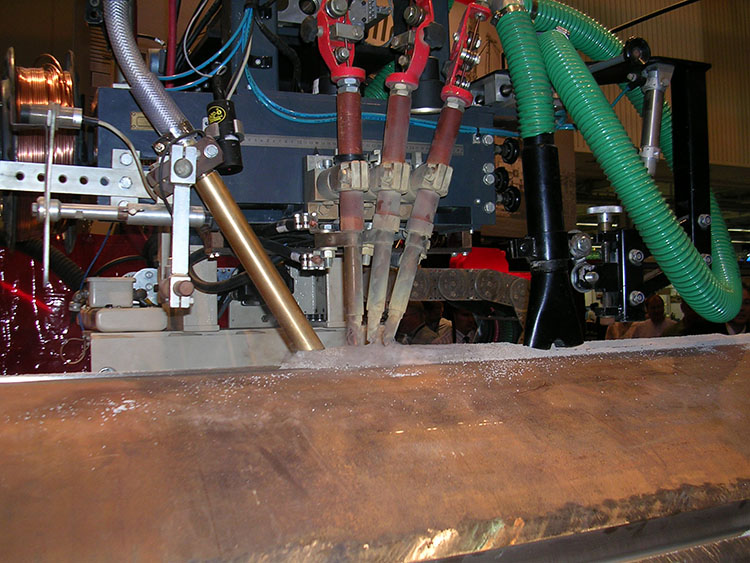

Submerged arc welding is a wire feeding mechanism that uses a granular flux to separate the arc from the air. As the name suggests, the arc is buried in the flux, meaning that when the parameters are set, the arc is invisible with the flow of a subsequent layer of flux.

The wire is continuously fed by a torch moving along the weld. Arc heating melts a section of the wire, part of the flux and the base material to form a molten pool, which condenses to form a weld covered with a layer of welding slag.

The thickness range of the welding material is 1/16 “-3/4″, which can be 100% penetration welding through single pass welding, if the wall thickness is not limited, it can be multi-pass welding, and carry out appropriate pre-treatment selection of the weld, and select the appropriate wire flux combination.

Flux and wire selection

Selecting the right flux and wire for a particular submerged arc welding process is critical to achieving the best results with that process. Although the submerged arc welding process alone is efficient, productivity and efficiency can be increased even based on the wire and flux used.

The flux not only protects the weld pool, but also contributes to the improvement of the mechanical properties and productivity of the weld. The formulation of flux is a huge influence on these factors, affecting current carrying capacity and slag release. Current carrying capacity means that the highest possible deposition efficiency and high quality weld profile can be obtained.

The slag release of a particular flux affects flux selection because some fluxes are better suited to some welding designs than others.

Flux selection options for submerged arc welding include active and neutral types of welding. A basic difference is that the active flux changes the chemistry of the weld, while the neutral flux does not.

Active flux is characterized by the inclusion of silicon and manganese. These elements help maintain weld tensile strength at high heat input, help weld remain smooth at high travel speeds and provide good slag release.

Overall, active flux can help reduce the risk of poor welding quality, as well as expensive post-weld cleaning and rework.

Keep in mind, however, that active flux is usually best for single or double pass welding. Neutral fluxes are better for large multi-pass welds because they help avoid forming brittle, crack-sensitive welds.

There are many wire options for submerged arc welding, each with advantages and disadvantages. Some wires are formulated for welding at higher heat inputs, while others are specially designed to have alloys that help the flux clean the weld.

Note that the chemical properties of the wire and the heat input interaction can affect the mechanical properties of the weld. Productivity can also be greatly improved by filling metal selection.

For example, using a metal-cored wire with a submerged arc welding process can increase the deposition efficiency by 15 to 30 percent compared to using a solid wire, while also providing a wider, shallower penetration profile.

Due to its high travel speed, the metal cored wire also reduces heat input to minimize the risk of welding distortion and burn-out. When in doubt, consult the filler metal manufacturer to determine which wire and flux combinations are best for a particular application.

Post time: Jun-27-2023