The preparation work before welding is as important as the welding process, which is directly related to the welding quality and effect of the finished product.

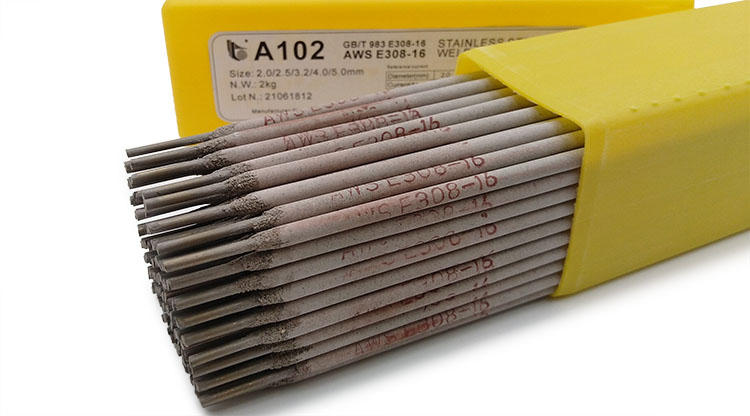

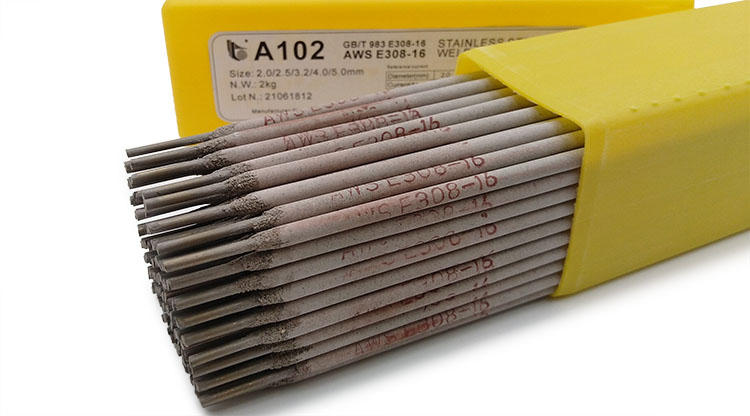

1. Electrode drying

The purpose of drying the electrode before welding is to remove the moisture in the wet electrode and reduce the hydrogen in the molten pool and weld to prevent pores and cold cracks. The drying process of electrodes with different coating types is different, and the drying process is carried out according to the process specified in the instruction manual of the electrode. It is recommended to dry according to the package instructions of Tianqiao welding electrodes.

2. Cleaning before welding

It refers to the removal of oil, rust, paint and water on the surface of the joint groove and its vicinity (within about 50mm) before welding. When welding with alkaline electrodes, the cleaning requirements are strict and thorough, otherwise pores and delayed cracks are easily generated. Acid electrodes are not very sensitive to rust. If the rust is relatively light and the quality of the weld is not high, it may not be removed.

3. Preheating

It refers to the process measures to properly heat the whole or part of the weldment before welding. Its main purpose is to reduce the cooling rate of the joint after welding, avoid the generation of hardened structure, and reduce welding stress and deformation. It is an effective way to prevent welding cracks. The need for preheating and the level of preheating temperature depend on the properties of the base metal, the electrode used and the restraint of the joint.

For general structures of low-rigid low-carbon steels and low-alloy high-strength steels with lower strength levels, preheating is generally not required. However, for structures with high rigidity or poor weldability that are prone to cracks, preheating is required before welding. Welding materials with high thermal conductivity, such as copper, aluminum and their alloys, sometimes require preheating, which can reduce the welding current and increase the penetration depth, and also facilitate the fusion of the weld metal and the base metal.

It must be pointed out that preheat welding is not only energy consumption, low productivity, but also poor labor conditions. Welding should be done without preheating or low temperature preheating whenever possible. The use of low hydrogen type electrodes can reduce the preheating temperature, because of its good crack resistance, but the water content of the electrode must be very low. As long as it is allowed, the electrode can be selected according to the principle of low combination, that is, the strength of the deposited metal is lower than that of the base metal, and the plasticity and toughness of the electrode are better than that of the base metal for welding, so that the preheating temperature can be reduced or no preheating can be used.

electrode,electrodes,welding,welding electrode,welding electrodes,welding rod,welding rods,welding electrode price,electrode welding,welding rod factory price,welding stick,stick welding,welding sticks,china welding rods,stick electrode,welding consumables,welding consumable,China electrode,welding electrodes China,carbon steel welding electrode,carbon steel welding electrodes,welding electrode factory,Chinese factory welding electrode,China welding electrode,China welding rod,welding rod price,welding supplies,wholesale welding supplies,global welding supplies,arc welding supplies,welding material supply,arc welding,steel welding,easy arc welding electrode,arc welding electrode,arc welding electrodes,vertical welding electrode,price of welding electrodes,cheap welding electrode,acid welding electrodes,alkaline welding electrode,cellulosic welding electrode,china welding electrodes,factory electrode,small size welding electrodes,welding materials,welding material,welding rod material,welding electrode holder,nickel welding rod,j38.12 e6013,welding rods e7018-1,welding stick electrode,welding rod 6010,welding electrode e6010,welding rod e7018,welding electrode e6011 ,welding rods e7018,welding electrodes 7018,welding electrodes e7018,welding rod 6013,welding rods 6013,welding electrode 6013,welding electrode e6013,6010 welding rod,6010 welding electrode,6011 welding rods,6011 welding electrodes,6013 welding rod,6013 welding rods,6013 welding electrode,6013 welding electrodes,7024 welding rod,7016 welding rod,7018 welding rod,7018 welding rods,7018 welding electrode,7018 welding electrodes,welding electrode e7016 ,e6010 welding rod,e6011 welding rod,e6013 welding rod,e7018 welding rod,e6013 welding electrode,e6013 welding electrodes,e7018 welding electrode,e7018 welding electrodes,J421 welding electrode,J422 welding electrodes,welding electrode J422,wholesale e6010,wholesale e6011,wholesale e6013,wholesale e7018,best welding electrode,best welding electrode J421,stainless steel welding electrode,stainless steel welding rod,stainless steel electrode,SS welding electrode,welding rods e307,welding electrode e312,309l welding rod,316 welding electrode,e316l 16 welding electrodes,cast iron welding electrode,aws Eni-Ci,aws Enife-Ci,surfacing welding,hard facing welding rod,hard surfacing welding,hardfacing welding, welding, welding,vautid welding,bohler welding,lco welding,miller welding,atlantic welding, welding,flux powder,welding flux,welding powder,welding electrode flux material ,welding electrode flux,welding electrode material,tungsten electrode,tungsten electrodes,welding wire,argon arc welding,mig welding,tig welding,gas arc welding,gas metal arc welding,electric are welding,electric arc welding,arc welding rods,carbon arc welding,e6013 welding rod uses,types of welding electrodes,flux core welding,types of electrodes in welding,welding supply,welding metal,metal welding,shielded metal arc welding,aluminum welding,welding aluminum with mig,aluminum mig welding,pipe welding,welding types,types of welding rod,all types of welding,welding rod types,6013 welding rod amperage,welding rods electrodes,welding electrode specification ,welding electrode classification ,welding electrode aluminium ,welding electrode diameter ,mild steel welding,stainless steel welding,e6011 welding rod uses,welding rods sizes,welding rods price,welding electrodes size,aws e6013,aws e7018,aws er70s-6,stainless steel welding wire,stainless steel mig welding wire,tig welding wire,low temp welding rod,6011 welding rod amperage,4043 welding rod,cast iron welding rod,western welding academy,sanrico welding rods,aluminium welding,aluminium welding rod,welding products,welding tech,welding factory

Post time: Feb-25-2022