The demand for steel in modern society is constantly increasing. In daily life, many things are made of metal, and many metals cannot be cast at the same time. Therefore, it is necessary to use electric welding for welding. The role of the electrode in the electric welding process is very important.

The welding rod is energized and melted at high temperature during arc welding, and fills the joints of the welding workpiece. Usually, the corresponding electrode is selected according to the material of the welding workpiece. Welding rod can be used for welding the same kind of steel or welding between different steels.

Sructure of Welding Electrode

The internal metal core of the welding rod and the external coating are composed. The welding core is a steel wire with a certain diameter and length. The main function of the welding core is to conduct current to heat and melt, and to fill and connect the workpiece.

The core material used for welding can generally be divided into carbon steel, alloy steel and stainless steel. However, in order to meet the welding requirements, there are special requirements for the material and metal elements of the welding core, and there are strict regulations on the content of some metal elements. Because the metal composition of the welding core will directly affect the quality of the weld.

There will be a layer of coating on the outside of the electrode, which is called a flux coat. Flux coat plays an important role. If the electric welding core is used to directly weld the workpiece, air and other substances will enter the molten metal of the electric welding core, and a chemical reaction will occur in the molten metal to directly cause the weld. Quality problems such as pores and cracks will impact the welding strength. Flux coat containing special elements will decompose and melt into gas and slag at high temperatures, which can effectively prevent air from entering and improve welding quality.

The ingredients of the flux coat include: hydrochloric acid, fluoride, carbonate, oxide, organic matter, iron alloy and other chemical powders, etc., mixed according to a certain formula ratio. The coating composition of different types of electrode coatings is also different.

There are three common types, namely slag agent, gas generating agent, and deoxidizer.

The slag agent is a compound that can protect the molten metal from air ingress when the electrode is melted, thereby improving the quality of welding.

The gas generating agent is mainly composed of starch and wood flour and other substances, which has a certain degree of reduction.

The deoxidizer is composed of ferro-titanium and ferromanganese. Generally, such substances can improve the wear resistance and corrosion resistance of metals.

In addition, there are other types of coatings on the electrode surface, and the composition and ratio of each type will be different.

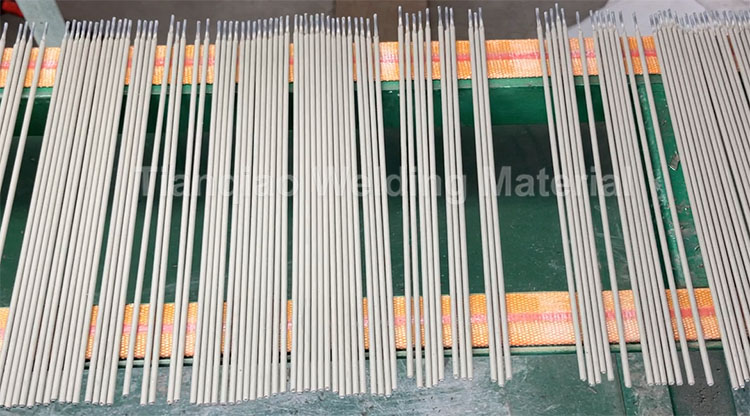

Manufacturing process of welding electrode

The manufacturing process of the welding rod is to manufacture the welding core and prepare the coating according to the design requirements of the welding rod, and apply the coating evenly on the welding core to make it meet the design requirements of the qualified welding rod.

First, the rolled steel bar is pulled out from the coiler, the rust on the surface of the steel bar is removed in the machine, and then it is straightened. The machine cuts the steel bar to the length of the electrode.

Next, a coating needs to be prepared on the surface of the electrode. The various raw materials of the coating are sieved to remove impurities, and then poured into the machine according to the proportion, and the binder is added at the same time. All powdered raw materials are thoroughly mixed by the agitation of the machine.

Put the mixed powder into a mold and press it into a cylindrical cylinder with a circular hole in the middle.

Put the pressed multiple barrels into the machine, put the welding cores neatly into the machine feed port, the welding cores enter the machine from the machine feed port in turn, and the wedling cores pass through the middle of the barrel due to extrusion. The machine evenly spreads the powder on the passing core to become a coating.

During the coating process of the welding rod, the entire welding core is coated with a layer of coating. In order to make the electrode easy to clamp and conduct electricity, the head and tail of the electrode need to be polished off the coating to expose the welding core.

After the coating is applied, the grinding head and the welding rod after grinding the tail will be evenly arranged on the iron frame and sent to the oven for drying.

In order to be able to easily distinguish the specifications and models of the electrode, it is necessary to print on the electrode. When the welding rod moves on the conveyor belt, each electrode is printed by a rubber printing roller on the conveyor belt.

After the welding rod model is printed, the welding rod can be packaged and sold after passing the inspection.

Tianqiao brand welding electrodes have excellent performance, stable quality, elegant welding molding, and good slag removal, good ability to resist rust, Stomata and crack, good and stable deposited metal mechanics characters. Tianqiao brand welding materials meet customers’ warm welcome due to the excellent quality, outstanding performance and competitive price. Click here to view more about our products

Post time: Sep-03-2021