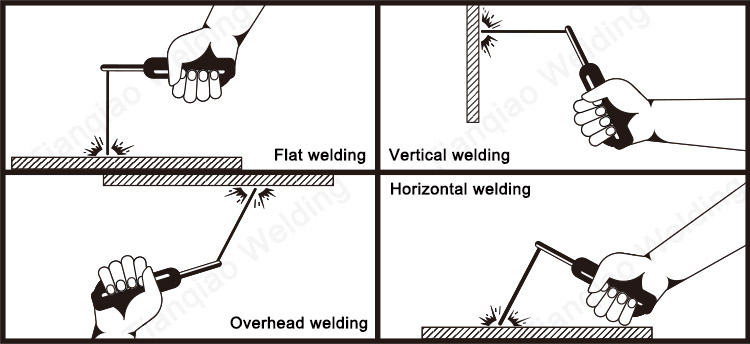

The welding position is referred to when welding, the relative spatial position of the weld to the welder.

Figure 1. Tianqiao welding positon

Figure 1. Tianqiao welding positon

There are flat welding, horizontal welding, vertical welding and overhead welding. Flat welding refers to the horizontal welding performed by the welder bowing his head, so it is also called downhand welding; for the weld in the T-shaped connection, the T-shaped weldment is often placed at 45° to form the welding position of the downward welding seam, so called ship welding. Horizontal welding refers to the horizontal welding performed by the welder at approximately the same height as the arm. Vertical welding refers to the bottom-up vertical welding by the welder. Overhead welding refers to the horizontal seam welding performed by the welder looking up. Flat welding is the easiest to ensure the welding quality, horizontal welding is the second, vertical welding is the third, and overhead welding is the most difficult to ensure quality and should be avoided as much as possible.

Figure 2. Tianqiao flat welding

Figure 2. Tianqiao flat welding

Flat welding

Welding characteristics of flat welding:

1. The weld metal mainly relies on its own weight to transition to the molten pool.

2. The shape and metal of the molten pool are easy to maintain and control.

3. For welding metals with the same thickness, the welding current in the flat welding position is larger than that in other welding positions, and the production efficiency is high.

4. The slag and molten pool are prone to mixing, especially when welding flat fillet welds, the slag is easy to lead and form slag inclusion.

*It is not easy to distinguish the slag of acid welding rod from the molten pool; the two of alkaline welding rods are relatively clear; the HG20581 standard clearly states that acid welding rods cannot be used in Class II and III vessels.

5. Improper welding parameters and operations can easily lead to defects such as weld bead, undercut, and welding deformation.

6. When the back side of single-side welding is freely formed, the first weld is prone to uneven penetration procedures and poor back molding.

The welding points of flat welding:

1. According to the thickness of the plate, a larger diameter electrode and a larger welding current can be used.

2. When welding, the welding rod and the weldment form an angle of 60~80°, and the separation of slag and liquid metal is controlled to prevent the slag from appearing in advance.

3. When the plate thickness is less than or equal to 6mm, the butt flat welding generally has a type I groove, and the front welding seam should be short-arc welding with a φ3.2~4 electrode, and the penetration depth can reach 2/3 of the plate thickness; before the back is sealed, It is not necessary to clean the roots (except for important structures), but the slag must be cleaned up and the current can be larger.

4. If there is unclear mixing of slag and molten pool metal in butt flat welding, the arc can be elongated, the electrode can be tilted forward, and the molten slag can be pushed to the back of the molten pool to prevent slag inclusion.

5. When welding horizontally inclined welds, upslope welding should be used to prevent slag inclusion and molten pool from moving forward to avoid slag inclusion.

6. When using multi-layer and multi-pass welding, pay attention to the number of welding passes and welding sequence, and each layer should not exceed 4~5mm.

7. For flat-angle welded joints of T type, corner joint, and overlap joint, if the thickness of the two plates is different, the angle of the welding rod should be adjusted to deflect the arc to one side of the thick plate, so that the two plates are heated evenly.

8. The correct choice of shipping method

(1) When the welding thickness is less than or equal to 6mm, type I groove butt flat welding. When double-sided welding is adopted, the front welding seam adopts a straight line, which is slightly slower; the back welding seam also adopts a straight line, and the welding current is slightly larger. , Faster.

(2) When the thickness of the plate is ≤6mm, when opening other forms of grooves, multi-layer welding or multi-layer multi-pass welding can be used. The first layer of bottom welding should use small current electrode, small standard current, straight line or sawtooth. Shape transport bar welding. For filling layer welding, a larger diameter electrode and short arc welding with larger welding current can be selected.

(3) When the size of the leg of the flat fillet welding of the T-joint is less than 6mm, single-layer welding can be used, and the linear, oblique ring or zigzag-shaped transport method can be used; when the size of the leg is larger, multi-layer welding or multi-layer welding should be used. Multi-pass welding, bottom welding adopts linear strip transportation method, and the filling layer can choose oblique sawtooth or oblique circular strip transportation.

(4) In general, multi-layer and multi-pass welding should be welded by the straight-line transport method.

Mild steel electrodes suitable for flat welding are AWS E6013, AWS E6010, AWS E6011, AWS E7018.

Figure 3. Tianqiao vertical welding

Figure 3. Tianqiao vertical welding

Vertical welding

The welding characteristics of vertical welding:

1. The molten pool metal and molten slag fall due to their own weight and are easy to separate.

2. When the temperature of the molten pool is too high, the molten pool metal is easy to drip down to form defects such as weld bead, undercut, slag inclusion, etc., and the weld is uneven.

3. The root of the T-joint weld is easy to form incomplete penetration.

4. The degree of penetration is easy to grasp.

5. Welding productivity is lower than flat welding.

The main points of vertical welding:

1. Maintain the correct welding rod angle;

2. In production, vertical vertical welding is commonly used, and vertical vertical welding requires special welding rods to ensure the quality of the weld. The welding current for vertical up welding is 10~15% smaller than that for flat welding, and a smaller electrode diameter (<φ4mm) should be selected

3. Use short arc welding to shorten the distance from the droplet to the molten pool.

4. Use the correct shipping method.

(1) T-groove butt joint (usually used for thin plates) when vertical welding is performed, linear, zigzag, crescent-shaped strip welding is commonly used, and the maximum arc length is not more than 6mm.

(2) When opening other forms of groove butt vertical welding, the first layer of weld is often welded by broken, crescent-shaped and triangular-shaped strip welding with small swing. Later, each layer can be used for crescent or zigzag striping.

(3) During vertical welding of T-shaped joints, the welding rod should have an appropriate residence time on both sides and top corners of the welding seam, and the swing amplitude of the welding rod should not be greater than the width of the welding seam. The operation of the welding rod is similar to that of other vertical welding with grooves.

(4) When welding the cover layer, the surface shape of the weld is determined by the method of transportation. Crescent-shaped strips can be used for welding seam surfaces with higher requirements; zigzag strips can be used for flat surfaces (the concave shape in the middle is related to the pause time).

Mild steel electrodes suitable for vertical welding are AWS E6013, AWS E6010, AWS E6011, AWS E7018, especially E6011 is suitable for vertical up-bottom welding.

Figure 4. Tianqiao overhead welding

Overhead welding

Welding characteristics of overhead welding:

1. The molten metal falls due to gravity, and the shape and size of the molten pool should not be controlled.

2. It is difficult to transport the strip, and the surface of the weldment is not suitable for welding.

3. Defects such as slag inclusion, incomplete penetration, weld bead and poor weld formation are easy to appear.

4. The molten weld metal splashes and spreads, which can easily cause scalding accidents.

5. The efficiency of overhead welding is lower than that of other positions.

Welding points of overhead welding:

1. Overhead welding of butt welds. When the thickness of the weldment is less than or equal to 4mm, use type I grooves and use φ3.2mm welding rods with moderate welding current; when the welding thickness is greater than or equal to 5mm, multi-layer and multi-pass welding should be used.

2. The welding seam of T-shaped joint is overhead welding. When the welding foot is less than 8mm, single-layer welding should be used, and when the welding foot is larger than 8mm, multi-layer and multi-pass welding should be used.

3. According to the specific situation, adopt the correct shipping method:

(1) When the size of the welding foot is small, the linear or linear reciprocating type is used to complete the single-layer welding; when the size of the welding foot is large, the multi-layer welding or multi-layer multi-pass welding can be used, and the first layer should be used Straight line transport, other layers can choose oblique triangle or oblique ring transport method.

(2) No matter which kind of transportation method is adopted, the weld metal should not be too much every time it passes to the molten pool.

Mild steel electrodes suitable for overhead welding are AWS E6013, AWS E6010, AWS E6011, AWS E7018

Figure 5. Tianqiao horizontal welding

Figure 5. Tianqiao horizontal welding

Horizontal welding

Welding characteristics of horizontal welding:

1. The molten metal easily falls on the groove due to its own weight, causing undercut defects on the upper side, and teardrop-shaped weld bead or incomplete penetration defects on the lower side.

2. Molten metal and slag are easy to separate, a little like vertical welding.

Key points of horizontal welding:

1. Butt joint horizontal welding grooves are generally V-shaped or K-shaped, butt joints with a plate thickness of 3~4mm can be welded on both sides with type I grooves.

2. Use small diameter welding rod, the welding current is smaller than flat welding, short arc operation, can better control the flow of molten metal.

3. When welding thick plates, in addition to the bottom weld, it is advisable to use multi-layer and multi-pass welding.

4. For multi-layer and multi-pass welding, special attention should be paid to controlling the overlap distance between the weld passes. For each overlap welding, start welding at 1/3 of the previous weld to prevent unevenness.

5. According to the specific situation, maintain the proper welding rod angle, and the welding speed should be slightly blocky and uniform.

6. Use the correct shipping method.

(1) For Type I butt horizontal welding, it is better to use a reciprocating linear strip method for the front welding seam; straight or small oblique circular strips should be used for thicker parts, and straight strips on the back side, and the welding current can be increased appropriately.

(2) Use other bevel butt horizontal welding. When the gap is small, the bottom welding can use straight strips; when the gap is large, the bottom layer adopts reciprocating linear strips; when the other layers are multi-layer welding, the inclined strip can be used. Straight-line transport should be used for circular transport of strips and multi-layer and multi-pass welding.

Mild steel electrodes suitable for horizontal welding are AWS E6013, AWS E6010, AWS E6011, AWS E7018

Post time: Jul-21-2021