-

Welding stress and distortion is the stress generated in welded components due to welding. It includes internal stresses generated during the welding process and changes in shape and size caused by the welding heat process. The non-uniform temperature field during welding, and the resulting l...Read more »

-

1. What is arc striking? What are the ways to start an arc? What should you pay attention to when striking an arc? The process of igniting and producing a stable arc is called arc ignition. There are two arc ignition methods: scratch arc ignition method and direct arc ignition method. For the ...Read more »

-

How to Select Welding Materials for Dual-Grade Austenitic Stainless Steel —In The Case of 304/304L and 316/316L The key to selecting dual-grade stainless steel welding consumables lies in understanding their fundamental nature: they simultaneously fulfil the mechanical properties of standard gra...Read more »

-

Cast iron is an early used structural material. Many parts of mechanical equipment are made of cast iron. At the same time, the repair welding of cast iron parts is still a common problem. 1 Classification of cast iron and its typical materials Cast iron is an iron-carbon alloy with carbon conten...Read more »

-

In today’s world where welding technology is changing with each passing day, Shielded Metal Arc Welding (SMAW) is still active in the industrial field with its unique vitality. From steel structure welding of skyscrapers to emergency repairs of field oil pipelines, this process, which was b...Read more »

-

Welding material standards are an important basis for ensuring welding quality and safety. Different countries or regions have formulated corresponding standards according to their own industrial needs. The following are several common welding material standards and their characteristics: 1. ISO ...Read more »

-

We promise to strictly control the quality to ensure that every product meet the standard. In the meantime, we arrange production efficiently and deliver on time, so that you can receive the goods with peace of mind and use them with satisfaction. Read more »

-

Flux-cored welding wire first appeared in the United States and Germany in the 1920s. However, it was not until the 1950s that it was really widely used in industrial production, especially after the 1960s and 1970s. With the emergence of fine-diameter (below φ2.0mm) all-position flux-cored weldi...Read more »

-

-

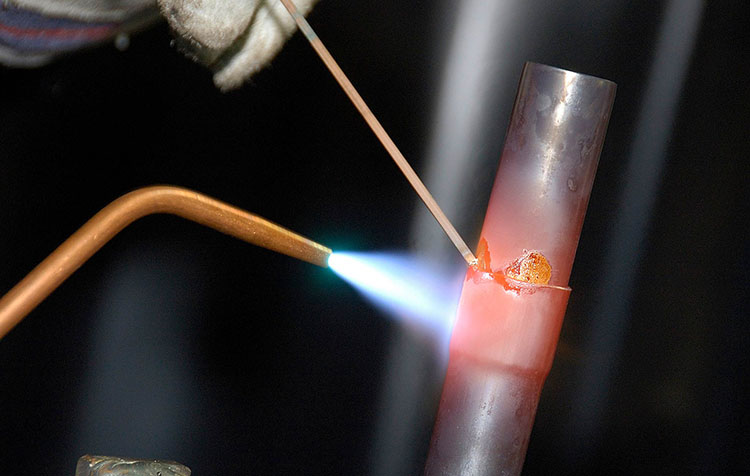

The energy source of brazing can be chemical reaction heat or indirect heat energy. It uses a metal with a melting point lower than that of the material to be welded as the solder. After heating, the solder melts, and the capillary action pushes the solder into the gap between the contact surface...Read more »