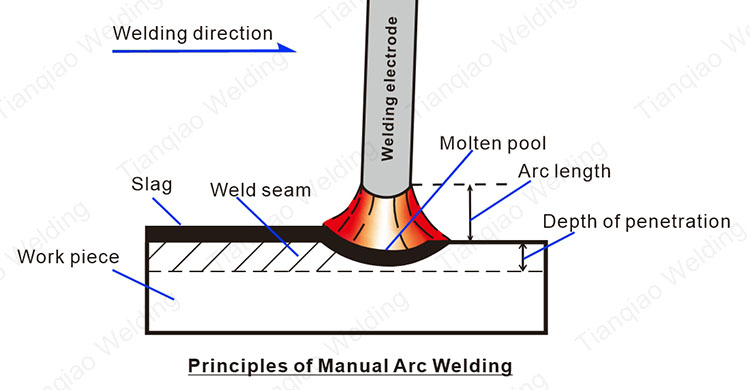

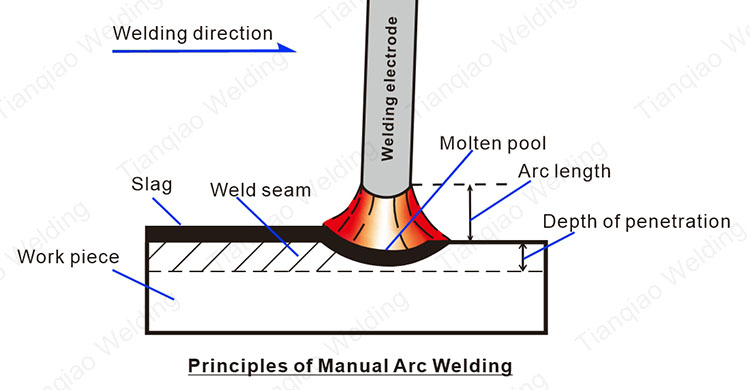

SMAW, also be well known as electrode arc welding, is a fusion welding method in which the arc is induced by the electrode and the welding parts are melted by the arc heat. It is the most widely used and common welding method at present.

Arc is an air conduction phenomenon. The welding arc is a strong and persistent discharge phenomenon generated in the gas medium between the electrode and the workpiece. During the welding process, the electrode and the weldment are respectively connected to the two electrodes of the welding power source. When the welding core of the electrode contacts the surface of the weldment, the circuit is turned on, and a large short-circuit current is generated at the same time. Since there is a certain resistance at the contact, according to Q=I2Rt, a large amount of heat will be generated there, and the heat will rapidly heat up and melt the contact. When the electrode is lifted by 2~4mm, the gas medium between the electrode and the weldment is ionized, producing conductive electrons and positive ions. Under the action of the electric field, the electrons move to the anode, and the positive ions move to the cathode. They collide and recombine continuously, converting kinetic energy into heat energy, thereby generating strong light and high heat, and forming an arc between the end of the electrode and the weldment.

The arc melts the end of the electrode and the corresponding weldment at the same time. The weld metal melts to form a molten pool, and the electrode metal melts to form a droplet. The molten droplets enter the molten pool under the action of gravity and arc blowing force, fuse with the metal of the weldment, and form a weld after solidification. During the welding process, the coating melts to form slag and a large amount of gas is generated, which protects and metallurgically treats the molten pool metal.

The welding arc consists of three parts: the cathode area, the anode area and the arc column area. The cathode area emits electrons, and the temperature is low, about 2400K; the anode area accepts electrons, and the temperature is high, about 2600K; the center temperature of the arc column area is the highest, about 6000~8000K.

When using DC arc welding power source (such as arc welding rectifier) for welding, there are two connection methods: positive connection and reverse connection. Positive connection is the connection method in which the electrode is connected to the negative electrode and the workpiece is connected to the positive electrode. Since the positive electrode accepts electrons and generates more heat, the weldment is easy to penetrate, so this connection method is often used for welding thicker workpieces. Reverse connection is the connection method in which the electrode is connected to the positive electrode and the workpiece is connected to the negative electrode. Since the heat generated by the electrons emitted by the negative electrode is less, the weldment is not easy to burn through, so this connection method is often used for welding thin workpieces.

The heat generated by the welding arc is proportional to the product of the arc voltage and the welding current (ie, Q=IUt). Usually, the voltage between the weldment and the electrode when the arc is stably burned is called the arc voltage, and the arc voltage is usually in the range of 20~35V. Because the arc voltage changes little, the arc heat is mainly adjusted by adjusting the welding current in production.

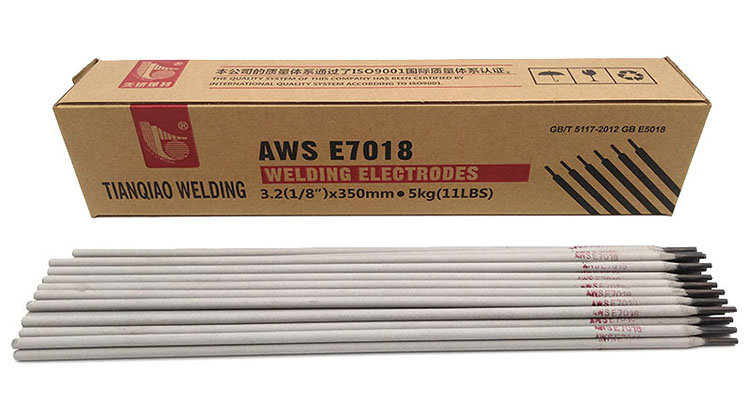

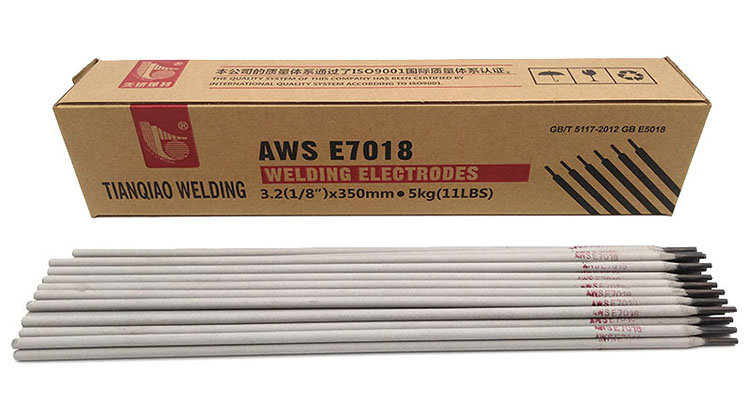

electrode,electrodes,welding,welding electrode,welding electrodes,welding rod,welding rods,welding electrode price,electrode welding,welding rod factory price,welding stick,stick welding,welding sticks,china welding rods,stick electrode,welding consumables,welding consumable,China electrode,welding electrodes China,carbon steel welding electrode,carbon steel welding electrodes,welding electrode factory,Chinese factory welding electrode,China welding electrode,China welding rod,welding rod price,welding supplies,wholesale welding supplies,global welding supplies,arc welding supplies,welding material supply,arc welding,steel welding,easy arc welding electrode,arc welding electrode,arc welding electrodes,vertical welding electrode,price of welding electrodes,cheap welding electrode,acid welding electrodes,alkaline welding electrode,cellulosic welding electrode,china welding electrodes,factory electrode,small size welding electrodes,welding materials,welding material,welding rod material,welding electrode holder,nickel welding rod,j38.12 e6013,welding rods e7018-1,welding stick electrode,welding rod 6010,welding electrode e6010,welding rod e7018,welding electrode e6011 ,welding rods e7018,welding electrodes 7018,welding electrodes e7018,welding rod 6013,welding rods 6013,welding electrode 6013,welding electrode e6013,6010 welding rod,6010 welding electrode,6011 welding rods,6011 welding electrodes,6013 welding rod,6013 welding rods,6013 welding electrode,6013 welding electrodes,7024 welding rod,7016 welding rod,7018 welding rod,7018 welding rods,7018 welding electrode,7018 welding electrodes,welding electrode e7016 ,e6010 welding rod,e6011 welding rod,e6013 welding rod,e7018 welding rod,e6013 welding electrode,e6013 welding electrodes,e7018 welding electrode,e7018 welding electrodes,J421 welding electrode,J422 welding electrodes,welding electrode J422,wholesale e6010,wholesale e6011,wholesale e6013,wholesale e7018,best welding electrode,best welding electrode J421,stainless steel welding electrode,stainless steel welding rod,stainless steel electrode,SS welding electrode,welding rods e307,welding electrode e312,309l welding rod,316 welding electrode,e316l 16 welding electrodes,cast iron welding electrode,aws Eni-Ci,aws Enife-Ci,surfacing welding,hard facing welding rod,hard surfacing welding,hardfacing welding, welding, welding,vautid welding,bohler welding,lco welding,miller welding, welding, welding,flux powder,welding flux,welding powder,welding electrode flux material ,welding electrode flux,welding electrode material,tungsten electrode,tungsten electrodes,welding wire,argon arc welding,mig welding,tig welding,gas arc welding,gas metal arc welding,electric are welding,electric arc welding,arc welding rods,carbon arc welding,e6013 welding rod uses,types of welding electrodes,flux core welding,types of electrodes in welding,welding supply,welding metal,metal welding,shielded metal arc welding,aluminum welding,welding aluminum with mig,aluminum mig welding,pipe welding,welding types,types of welding rod,all types of welding,welding rod types,6013 welding rod amperage,welding rods electrodes,welding electrode specification ,welding electrode classification ,welding electrode aluminium ,welding electrode diameter ,mild steel welding,stainless steel welding,e6011 welding rod uses,welding rods sizes,welding rods price,welding electrodes size,aws e6013,aws e7018,aws er70s-6,stainless steel welding wire,stainless steel mig welding wire,tig welding wire,low temp welding rod,6011 welding rod amperage,4043 welding rod,cast iron welding rod,western welding academy,sanrico welding rods,aluminium welding,aluminium welding rod,welding products,welding tech,welding factory

Post time: Dec-30-2022