When welding stainless steel, the performance of the electrode must match the purpose of the stainless steel. Stainless steel electrode must be selected according to the base metal and working conditions (including working temperature, contact medium, etc.).

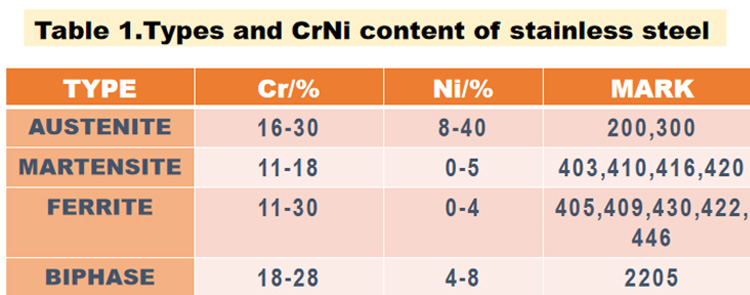

Four types of stainless steel as well as alloying elements are used

Stainless steel can be divided into four types: Austenitic, martensitic, ferritic and biphase stainless steel, as shown in Table 1.

This is based on the metallographic structure of stainless steel at room temperature. When mild steel is heated to 1550 ° F, the structure changes from the room-temperature ferrite phase to the austenitic phase. When cooled, the mild steel structure is converted back into ferrite. Austenitic structures present at high temperatures are non-magnetic and have less strength and toughness than room-temperature ferrite structures.

How to choose the right stainless steel welding material?

If the base material is identical, the first rule is “match the base material”. For example, select the welding material for 310 or 316 stainless steel.

For welding dissimilar materials, the criterion of selecting the base material with high alloying element content is followed. For example, if 304 or 316 stainless steel is welded, select type 316.

But there are also many do not follow the “matching base material” principle of special circumstances, then it is necessary to “consult the welding material selection table”. For example, type 304 stainless steel is the most common base metal, but there is no Type 304 electrode.

If the welding material is matched with the base material, how to choose the welding material to weld 304 stainless steel?

When welding 304 stainless steel, use type 308 welding material, because the additional elements in 308 stainless steel can better stabilize the weld area.

308L is also an acceptable option. L means low carbon content, 3XXL stainless steel carbon content ≤0.03%, and the standard 3XX stainless steel can contain up to 0.08% carbon content.

Because L-shaped welding belongs to the same type of classification as non-L-shaped welding, manufacturers should give special consideration to using L-shaped welding because its low carbon content reduces the tendency to intergranular corrosion (see Figure 1).

How to weld stainless steel and carbon steel?

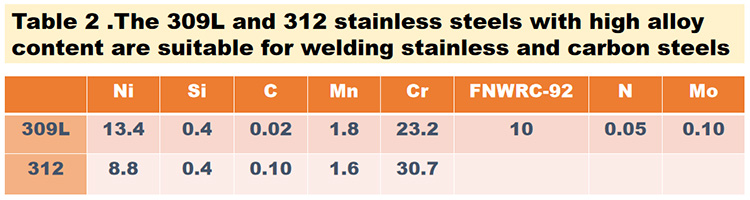

To reduce costs, some structures weld a layer of corrosion resistance to the surface of the carbon steel. When welding a base material without alloying elements with a base material with alloying elements, use a welding material with a higher alloying content to balance the dilution rate in the weld.

When welding carbon steel with 304 or 316 stainless steel and other dissimilar stainless steel (see Table 2), 309L welding material should be considered in most cases. If you want to get a higher Cr content, choose type 312.

What is an appropriate pre-weld cleaning operation?

When welding with other materials, first remove oil, marks and dust with a chlorine-free solvent. In addition, the first thing to pay attention to when welding stainless steel is to avoid being polluted by carbon steel and affect the corrosion resistance. Some companies store stainless steel and carbon steel separately to avoid cross-contamination. Use special grinding wheels and brushes for stainless steel when cleaning the area around the groove. Sometimes the joint needs to be cleaned a second time. Because the electrode compensation operation of stainless steel welding is more difficult than that of carbon steel welding, the joint cleaning is very important.

Post time: May-09-2023