Q1: What is welding material? What to include?

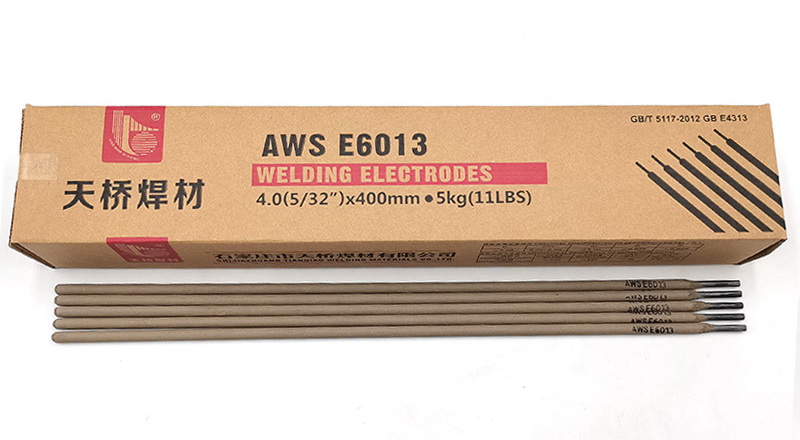

Answer: Welding materials include welding rods, welding wires, fluxes, gases, electrodes, gaskets, etc.

Q2: What is acid electrode?

Answer: The coating of the acid electrode contains a large amount of acid oxides such as SiO2, TiO2 and a certain amount of carbonate, and the alkalinity of the slag is less than 1. Titanium electrodes, calcium titanium electrodes, ilmenite electrodes and iron oxide electrodes are all acid electrodes.

Q3:What is alkaline electrode?

Answer: Alkaline electrode coating contains a large amount of alkaline slag-forming materials such as marble, fluorite, etc., and contains a certain amount of deoxidizer and alloying agent. Low-hydrogen type electrodes are alkaline electrodes.

Q4: What is cellulose electrode?

Answer: The electrode coating has a high cellulose content and a stable arc. It decomposes and produces a large amount of gas to protect the weld metal during welding. This type of electrode produces very little slag and is easy to remove. It is also called a vertical downward welding electrode. It can be welded in all positions, and vertical welding can be welded downwards.

Q5: Why must the electrode be dried strictly before welding?

Welding rods tend to deteriorate the process performance due to moisture absorption, resulting in unstable arc, increased spatter, and easy to produce pores, cracks and other defects. Therefore, the welding rod must be dried strictly before use. Generally, the drying temperature of the acid electrode is 150-200℃, and the time is 1 hour; the drying temperature of the alkaline electrode is 350-400℃, the time is 1-2 hours, and it is dried and placed in an incubator at 100-150℃ Inside, take it as you go.

Q6: What is welding wire?

Answer: It is a metal wire that is used as a filler metal during welding and used for conducting electricity at the same time-called welding wire. There are two types: solid wire and flux-cored wire. Commonly used solid welding wire model: (GB-national standard of China) ER50-6 (class: H08Mn2SiA). (AWS-American Standard) ER70-6.

Q7: What is flux cored welding wire?

Answer: A kind of welding wire made from thin steel strips rolled into round steel pipes and filled with a certain composition of powder.

Q8: Why is the flux cored wire protected by carbon dioxide gas?

Answer: There are four types of flux-cored welding wire: acidic flux-cored gas shielded welding wire (titanium type), alkaline flux-cored gas shielded welding wire (titanium calcium type), metal powder type flux-cored gas shielded welding wire and flux-cored self-shielded welding wire. The domestic titanium type flux-cored gas shielded welding wire is generally protected by CO2 gas; other flux-cored welding wires are protected by mixed gas (please refer to the flux-cored wire specification). The metallurgical reaction of each gas slag formula is different, please do not use wrong protection gas. Flux-cored welding wire gas slag combined protection, good welding seam formation, high comprehensive mechanical properties.

Q9: Why are there technical requirements for the purity of carbon dioxide gas?

Answer: Generally, CO2 gas is a by-product of chemical production, with a purity of only about 99.6%. It contains traces of impurities and moisture, which will bring defects such as pores to the weld. For important welding products, gas with CO2 purity ≥99.8% must be selected, with less pores in the weld, low hydrogen content, and good crack resistance.

Q10: Why have higher technical requirements for argon purity?

Answer: There are currently three types of argon on the market: plain argon (purity around 99.6%), pure argon (purity around 99.9%), and high-purity argon (purity 99.99%). The first two can be welded to carbon steel and stainless steel. High-purity argon must be used for welding non-ferrous metals such as aluminum and aluminum alloys, titanium and titanium alloys; to avoid oxidation of the weld and heat-affected zone, high-quality and beautiful weld formation cannot be obtained.

Post time: Jun-23-2021