Consider the physical properties, mechanical properties and chemical composition of the weld material

1. Structural steel welding, generally consider the principle of equal strength, choose to meet the requirements of the mechanical properties of the joint welding material.

2. For low carbon steel and low alloy steel between the welding joint of dissimilar steel, generally choose the corresponding welding consumables with the lower strength grade of steel.

3. For heat-resistant steel and stainless steel welding, in addition to considering the strength, but also consider the main chemical composition of the weld metal and the chemical composition of the parent material close.

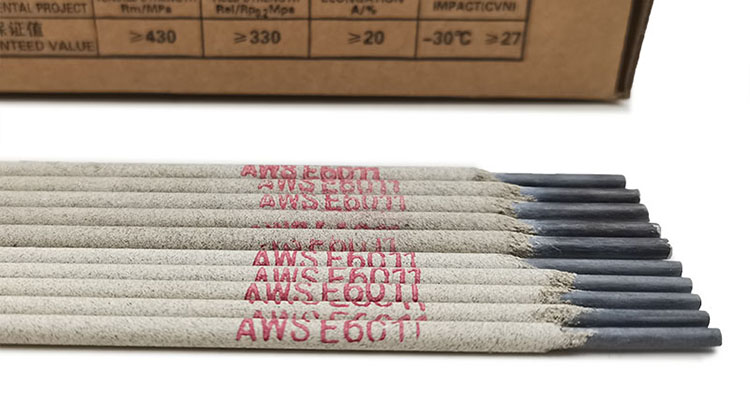

4. When the chemical composition of the parent material, such as carbon or sulfur, phosphorus and other harmful impurities are high, should choose a stronger crack resistance welding consumables. Such as low hydrogen type welding consumables.

Consider the working conditions of the welding and the use of performance

1. Welded parts in the case of dynamic load and impact load, in addition to the requirements to ensure the tensile strength, yield strength, impact toughness, plasticity are higher requirements. At this time should be selected with low-hydrogen welding material.

2. Welded parts in corrosive media, must be distinguished from the media type, concentration, working temperature and type of corrosion (general corrosion, intergranular corrosion, stress corrosion, etc.), so as to choose the appropriate stainless steel welding consumables.

3. When the weld works under wear conditions, it is necessary to distinguish between general wear or impact wear, intermetallic wear or abrasive wear, wear at room temperature or wear at high temperature, etc.. Should also consider whether to work in corrosive media, in order to choose the appropriate overlay welding consumables.

4. In the low temperature or high temperature welding parts, should choose to ensure that the low temperature or high temperature mechanical properties of the welding material.

Consider the complexity and structural characteristics of the welded parts, welded joint type, etc.

1. Complex shape or large thickness of the welded parts, due to its welding metal in the cooling contraction of the internal stress generated by the large, easy to produce cracks. Therefore, it is necessary to use welding consumables with good crack resistance, such as low-hydrogen type welding rod, high toughness welding rod.

2. For certain joints with small bevels, or joints with strict control of root penetration, the welding consumables with greater depth of fusion or penetration should be used.

3. Due to the constraints of some welding parts difficult to clean up, should consider the use of rust, oxidation and oil reaction is not sensitive to the welding material, such as acid welding rod, so as not to produce defects such as porosity.

Consider the spatial position of the weld

Some welding consumables are only suitable for welding in a certain position, other positions are less effective when welding, some welding consumables are able to weld in various positions, the characteristics of the welding position should be considered when choosing.

Consider welding working conditions, operating environment

1. There is no DC welding machine occasions, should use AC and DC dual-use welding material.

2. Some steel (such as pearlite heat-resistant steel) need to be post-weld stress relief heat treatment, but by the equipment conditions or its own structural constraints and cannot be carried out, should be selected with the base metal chemical composition of different welding consumables (such as austenitic stainless steel welding consumables), can be exempt from post-weld heat treatment.

3. Should be based on the construction site conditions, such as field operations, welding work environment, etc. to rational selection of welding consumables.

4. In places where both acidic and alkaline welding electrodes can be used, acidic welding electrodes should be used as far as possible in view of the high requirements of alkaline welding electrodes for operation techniques and construction preparation.

Consider the economics of welding

1. Try to use cost-effective welding consumables, provided that the performance of use is guaranteed.

2. Different welding consumables can be used for primary and secondary welds with different performance requirements, and do not pursue the full performance of the welding consumables unilaterally.

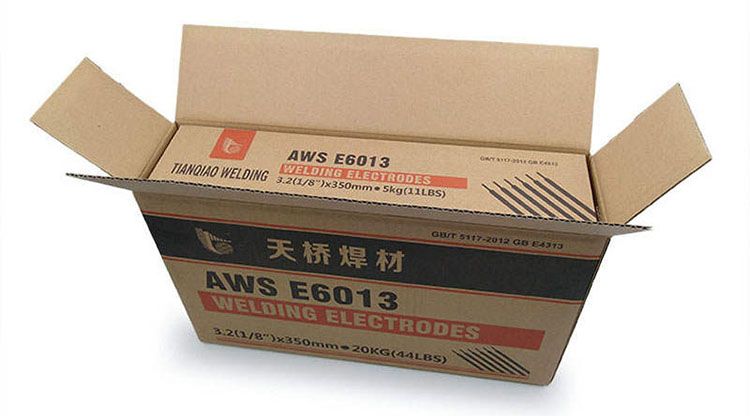

Consider welding efficiency

For structures with a large welding workload, high efficiency welding consumables should be used as far as possible when available, such as welding wire, iron powder welding rod, efficient stainless steel welding rod, etc.

Post time: Dec-21-2022